Skip to main content

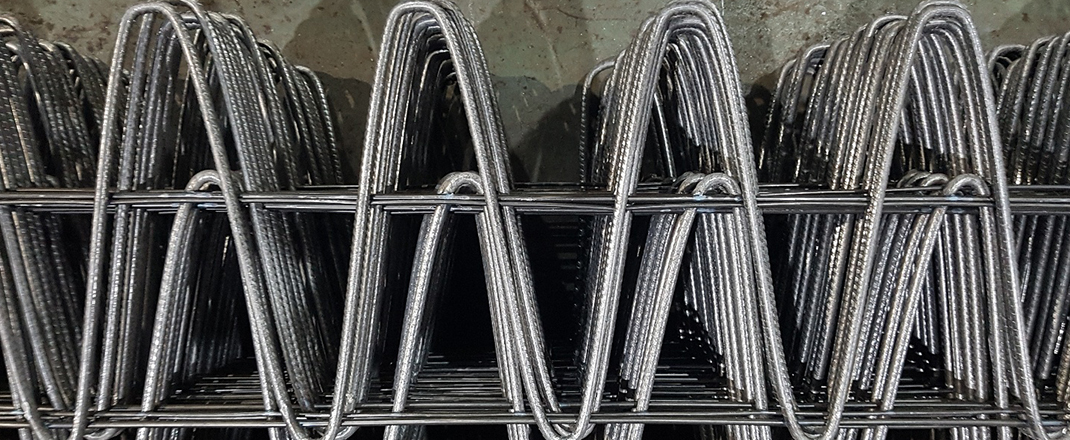

Background of BAR introduction

- In a rib-shaped slab, the rib portion requires shear reinforcement bars, but in the past, dozens of reinforcement bars were manually worked one by one, which required a lot of manpower and caused problems in quality deterioration.

- When shear reinforcement bars and main reinforcement bars were pre-assembled, they were connected only with tie lines, which made them become easily deformed during transportation, and thus could not maintain consistent quality.

Effect of applying bar

- Not only the shear reinforcement bars but also the main reinforcement bars are manufactured in one piece, which is economical as it reduces a lot of work time and labor.

- On-site bar placement is easy.

- It is structurally advantageous as the upper and lower fixation effects are good.

- The upper exposed surface of the shear reinforcement bar is of the closed type, so it does not interfere with walking, thus improving safety.

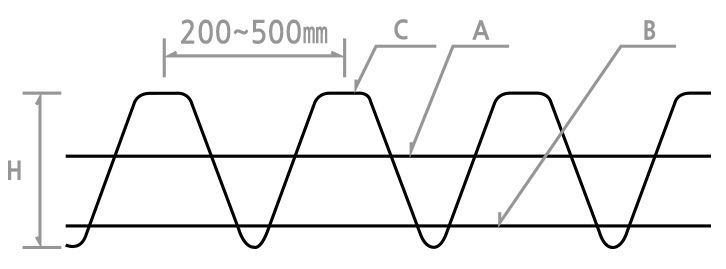

Features of lattice bar

- The ridge and pitch are integrated at regular intervals (200-500mm).

- The ridge section is processed horizontally, making on-site bar placement easy, and eliminating the need for a separate space bar.

- The lattice bar and lower main reinforcement bar are automatically welded.

- The lattice bar and lower main slab reinforcement bar are automatically welded.

Structural features of the lattice bar

| Lattice height(H) |

Upper bar(A) |

Lower bar(B) |

Lattice bar(C) |

| 250~800mm |

6~16mm |

6~16mm |

8~13mm |

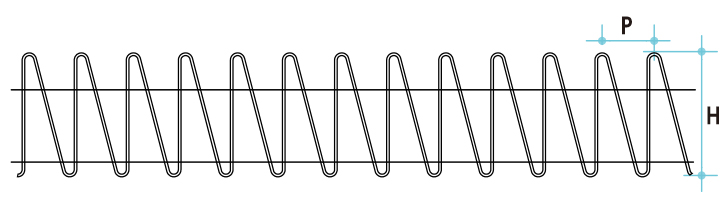

Structural features of N BAR

| Pitch(P) |

Height(H) |

Upper and lower bar |

Lattice bar(body) |

| 200, 250, 300, 400mm |

250~1000mm |

6~16mm |

8~13mm |

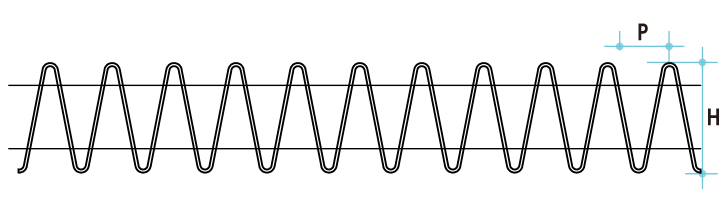

Structural features of W BAR

| Pitch(P) |

Height(H) |

Upper and lower bar |

Lattice bar(body) |

| 200, 250, 300, 400mm |

250~1000mm |

6~16mm |

8~13mm |