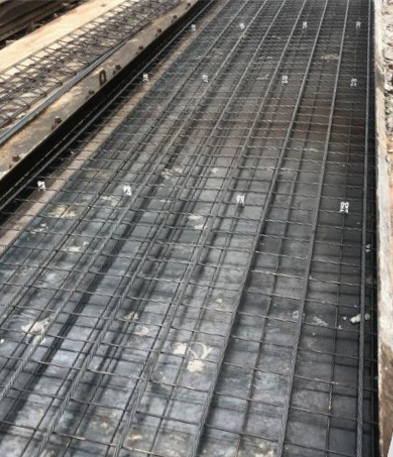

Wire mesh refers to a grid-shaped sheet in which vertical and horizontal lines are arranged at right angles using cold-rolled or draw-processed high-strength steel wires, and the intersections are joined by electric resistance welding. Plain Wire and Deformed Wire are used for welded wire mesh, and are classified into Plain Wire Fabric and Deformed Wire Fabric depending on the wire used.

Plain Wire Fabric is attached to concrete by a secure mechanical anchorage at each wire intersection, while Deformed Wire Fabric is also excellent for structural use, because not only the welded intersections but also the deformability of the wires play an important role in the adhesion and anchorage to concrete.

What is wire mesh?

Wire mesh manufacturing process

01

Drawing work

02

Straightening work

03

Welding work

04

Cutting work

05

Wire mesh

Wire mesh features and advantages

- In terms of work speed, it has the effect of significantly shortening the construction period compared to general reinforcement bar work.

- Concrete adhesion performance is improved, durability is improved, and it is excellent at preventing cracks.

- High-quality products are possible through a uniform production process, thus making it easy to precisely place bars and maintain quality.

- By manufacturing products optimized for design through custom manufacturing, it reduces the amount of work on site.

- Since it is taken out to the construction site as a finished product that has already been welded, installation is relatively simple and can be done by unskilled workers.

- It is a product with specifications suitable for construction sites of various structures and has a wide range of uses (in roads, tunnels, underground parking lots, office buildings, hotels, schools, hospitals, factories, P.Cs, etc.)

- Labor-cost reduction effect due to simplification of field work processes

Wire mesh(Welded wire mesh) specifications table

| Size Number | Dia of wire | Unit Weight | Wire weight in kg/㎡ Distance center to center of wire |

||||

|---|---|---|---|---|---|---|---|

| No. | mm | kg/m | 50mm | 75mm | 100mm | 150mm | 200mm |

| #10 | 3.2 | 0.063 | 2.52 | 1.68 | 1.26 | 0.84 | 0.63 |

| #9 | 3.5 | 0.075 | 3.00 | 2.00 | 1.50 | 1.00 | 0.75 |

| #8 | 4.0 | 0.098 | 3.92 | 2.61 | 1.96 | 1.30 | 0.98 |

| #7 | 4.5 | 0.125 | 5.00 | 3.33 | 2.50 | 1.66 | 1.25 |

| #6 | 4.8 | 0.142 | 5.68 | 3.79 | 2.84 | 1.89 | 1.42 |

| #5 | 5.3 | 0.173 | 4.61 | 3.46 | 2.30 | 1.73 | |

| #4 | 5.8 | 0.207 | 5.52 | 4.14 | 2.75 | 2.07 | |

| #3 | 6.4 | 0.253 | 5.06 | 3.37 | 2.53 | ||

| #2 | 7.0 | 0.302 | 6.04 | 4.01 | 3.02 | ||

| #1 | 7.5 | 0.347 | 6.94 | 4.62 | 3.47 | ||

Wire mesh(Welded wire mesh) production possible specifications

W/M production possible specifications

| Steel wire thickness | Netting | Width | Length |

|---|---|---|---|

| ∮3~16㎜ | 75~300㎜ | 1,000~2,500㎜ | 1,000~16,000㎜ |

*Detailed specifications for each steel wire thickness (wire diameter) may vary, so please discuss before production.

Wire mesh facilities & uses

· Floor paving reinforcement bar

· For P.Cs

· For architectural structures

· Road paving

· Reinforcement bar for retaining walls and waterways

· Various types of concrete reinforcement bar

· Other